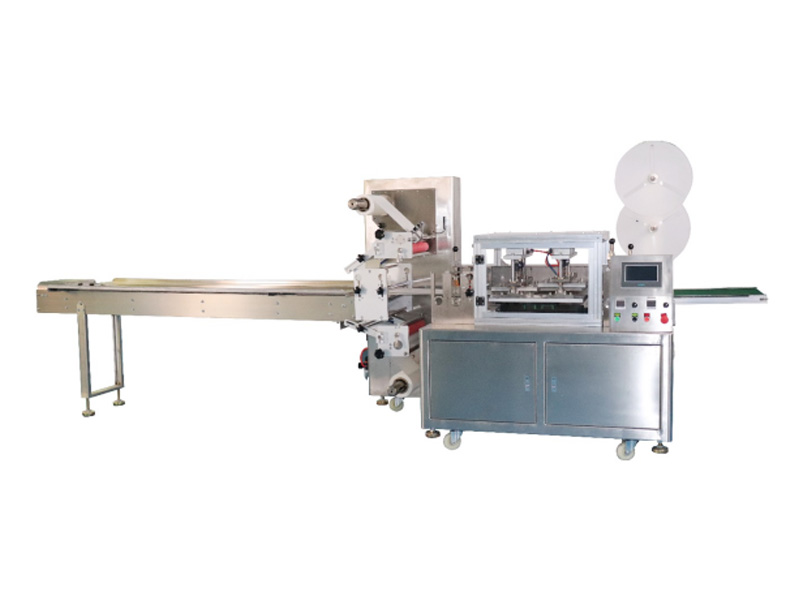

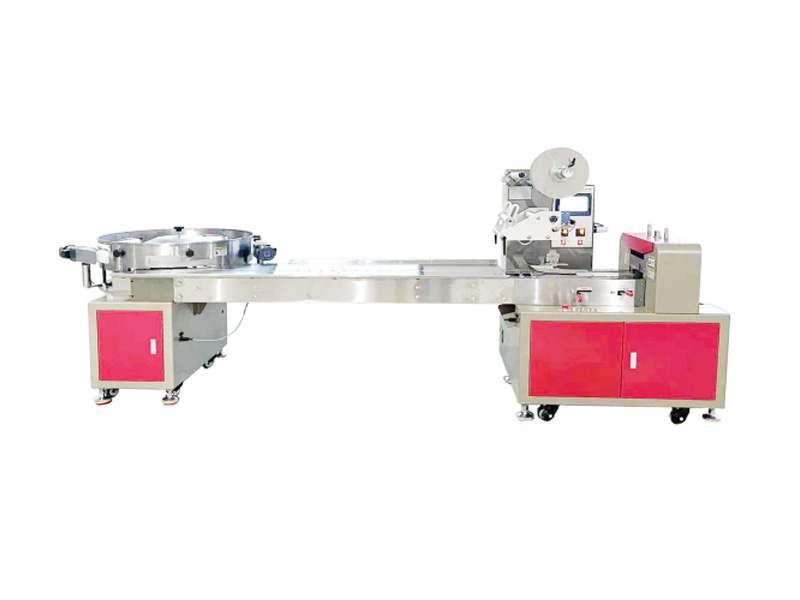

The main performance of mask packaging machine:

The main performance of mask packaging machine:

1. The mask packaging machine is compact in structure, stable in performance and simple in operation; dual frequency conversion control, the bag length can be set and cut immediately, no need to adjust the empty run, one step in place, saving time and film;

2. The mask packaging machine adopts imported electrical appliances and touch human-machine interface. The parameter setting is convenient and quick. The fault self-diagnosis function is clear at a glance. The high-sensitivity photoelectric eye color mark tracking makes the sealing and cutting position more accurate. The temperature is controlled by PID, which is better suited. Various material envelopes;

3. Mask packaging machine positioning stop function, no sticking knife, no film; rotation system is simple, work is more reliable, maintenance is more convenient;

4. All controls of the mask packaging machine are realized by software, which is convenient for function adjustment and technology upgrade, and never lags behind.

Structural features of mask packaging machine:

1. Mask packaging machine has high packaging efficiency, stable performance, convenient operation and maintenance, and low failure rate;

2. Mask packaging machine can run continuously for a long time;

3. Mask packaging machine has good sealing performance and beautiful packaging effect;

4. Mask packaging machine can print production date, inflation, etc. simultaneously;

5. Mask packaging machine is economical and affordable, with a wide range of packaging.

Product advantages of mask packaging machine:

1. Mask packaging machine is controlled by original three servo motors

2. Mask packaging machine is more intelligent, with higher packaging accuracy, wider adjustable range, more precise control, lower scrap rate, and better stability

3. As the mask packaging machine adopts the world's first fully open box structure, the transmission structure is clear at a glance, and maintenance is more convenient.

Mask packaging machine maintenance:

a. Before cleaning and wiping the machine, you must first turn off the power to ensure the safety of human and machine.

b. Wipe the work surface and outer surface of the machine with a clean, moistened cloth.

c. Use compressed air to remove product debris from the feeding mechanism and the middle and end seals.

d. Use a wire brush coated with oil to remove the film fragments adhering to the end seal knife.

Mask packaging machine attention issues:

1) Check the drive belt and flat belt for abrasion and replace with new ones if necessary.

2) Check all kinds of wearing parts and pay attention to timely replacement.

3) Check the wear of each transmission part and replace with new ones if necessary.

4) Check and tighten the electrical wiring, and clean the dust on the electrical components with compressed air